Technology in logistics

Logistics has always been a progressive sector. From the container revolution that transformed global shipping in the 1950s to the barcode system that streamlined warehouse operations in the 1970s, logistics repeatedly embraces technologies that some consider experimental. This isn’t coincidence. It’s necessity. In an industry where margins are tight and speed determines competitive advantage, early adoption is key to survival.

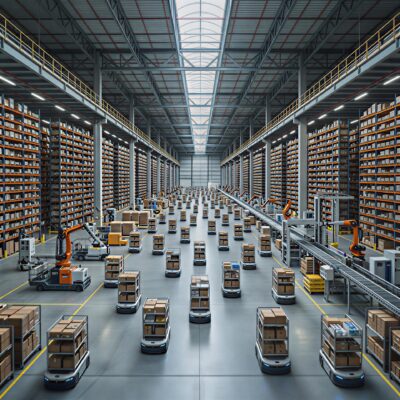

Today’s technological shift proves equally transformative. Autonomous mobile robots navigate warehouse floors. AI algorithms optimise delivery routes in real-time. Predictive maintenance systems prevent equipment failures before they occur. Yet many companies discover too late that their facilities cannot support the very technologies their competitors deploy successfully. The question isn’t whether to automate, but whether your property enables it.

At Necron Group, we recognise that technology integration must drive location strategy, not follow it. The facilities we develop today will determine which innovations are possible tomorrow.

Technology transforms logistics reality

Picture a typical Tuesday morning when someone, somewhere orders a phone charger. Within seconds, the order appears in an AI-powered inventory management system. An autonomous mobile robot receives routing instructions and navigates to the correct shelf. Computer vision verifies the item, eliminating picking errors. The charger is loaded onto a delivery vehicle following the optimal route. Real-time tracking notifies the customer when the driver approaches. Inventory updates flow across the entire network instantly.

Meanwhile, IoT sensors throughout the facility monitor equipment performance. Predictive maintenance systems analyse vibration patterns and thermal signatures, identifying potential failures hours before they occur. Temperature sensors ensure climate-sensitive products remain within specification. This level of operational excellence represents standard practice in properly equipped facilities.

Yet behind this efficiency lies deliberate infrastructure investment: data centres with substantial computing capacity, redundant fibre networks, advanced power distribution systems, flexible layouts, and continuous sensor networks feeding data to AI systems. None of this would be possible in facilities lacking proper infrastructure foundations. Traditional warehouses designed for manual operations cannot retrofit these systems affordably.

Why facility infrastructure determines automation success

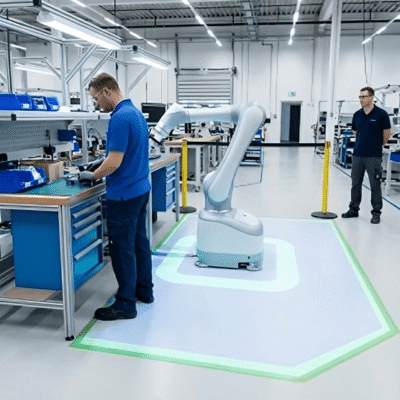

Modern robotics and AI are transforming warehouse operations, but deployment success depends heavily on facility readiness. Autonomous mobile robots can navigate independently and adapt to changing layouts. However, they demand reliable power infrastructure, robust connectivity networks, and real-time collision detection systems. Facilities must provide data centres for fleet management, redundant wireless networks preventing communication failures, and adequate electrical distribution supporting mass charging stations.

![]()

Collaborative robots work safely alongside human employees, handling repetitive tasks without requiring safety cages. Yet facilities deploying s need flexible space planning and robust connectivity for real-time safety monitoring. The challenge isn’t simply installing equipment; it’s ensuring the building infrastructure can support continuous operation at scale.

Pepijn Amse, sales manager at Robotics Benelux,emphasises a recurring pattern:“Whenever we visit existing facilities to design an automated system, the footprint is often underestimated. The safety zone surrounding moving arms is frequently overlooked, making insufficient space a serious constraint.” This morning, he had an appointment in the north of the Netherlands to install three robotic arms in a triangle configurationa. The available space proved inadequate, requiring costly custom modifications. Expenses that were entirely preventable through proper planning.

Critical infrastructure requirements

Physical space and ceiling height

Footprint is what experts call the necessary floor area for a complete robotic system. It is routinely underestimated. Safety zones surrounding moving equipment often demand far more space than the machines themselves. Ceiling height presents another critical constraint. Standard warehouses offer 8-10 metres of clearance. Modern automation systems require 12+ metres for conveyor systems, vertical storage, and robotic operations.

Pepijn Amse explains further: ”When a client wants a machine stacked on top of another, we need sufficient ceiling height. When installing conveyors above operations, height becomes non-negotiable. But many facilities simply cannot accommodate these installations.”

Floor specifications matter equally. Industrial robots demand floors supporting at least five tonnes per square metre. Uneven surfaces compromise precision. Permanent obstructions prevent layout reconfiguration as technologies evolve.

Power and connectivity infrastructure

Three-phase power availability determines whether industrial automation becomes feasible. Many existing logistics properties lack adequate electrical capacity. Retrofitting proves prohibitively expensive. Compressed air infrastructure supports pneumatic systems throughout modern facilities. Redundant internet connectivity ensures operations continue even during network failures.

IoT sensor networks require comprehensive data infrastructure. Facilities need local edge computing to process sensor data in real-time, enterprise system integration for maintenance scheduling, and robust wireless coverage throughout operations. Legacy properties retrofitting these capabilities encounter expensive complications. Facilities designed with sensor infrastructure from inception realise maintenance cost reductions immediately.

Layout flexibility

Technology evolves rapidly. Yesterday’s innovation becomes today’s standard. Facilities must adapt to unknown future requirements. This demands modular infrastructure: movable walls enabling layout reconfiguration, utility conduits accommodating new equipment, electrical systems with overcapacity, and floor space remaining uncluttered and free from permanent obstructions.

The Intellistore system is an automated, fully modular warehouse developed by Dutch company OBS-linQ. It demonstrates how facilities designed with vertical space efficiency enable dramatically improved performance. The cube-like structure achieves an exceptionally small int with minimal error. This innovation only succeeds in properties built to support it.

Future-proofing logistics properties

With a relocation on the horizon, you should remember that future-proofing requires infrastructure flexibility rather than predicting specific innovations. Consider utility infrastructure as investment in future capability, not just current operations. Building overcapacity into electrical systems, compressed air infrastructure, and water systems costs relatively little during initial development but becomes prohibitively expensive to retrofit.

Strategic considerations

Prioritise properties offering 12+ metres of ceiling height. Plan which areas within facilities will undergo automation: near docking stations, storage areas, or processing zones. Ensure three-phase power availability with substantial overcapacity. Install comprehensive data infrastructure supporting IoT sensor networks.

Automation is shifting labour markets, but staff needs evolve rather than disappear. Facilities should support training programmes where personnel transition into roles overseeing automated systems, managing data, and handling exceptions. This requires spaces for training infrastructure—a feature often overlooked during facility selection.

Pepijn Amse observes broader trends: ”Costs for robotics previously required 3-year payback periods. That’s shifting rapidly. Staff is so scarce and expensive that organisations can hardly find sufficient personnel. Automation improves business continuity, lightens workload and reduces human errors dramatically. Five-year payback periods are becoming acceptable. Economic pressure acerates automation adoption, making future-proof facilities increasingly valuable.”

Intelligent facility decisions

When assessing potential logistics properties, request specific technical documentation: clear ceiling heights throughout facilities, floor loading specifications, three-phase power availability and capacity, compressed air infrastructure, layout dimensions for major operational areas, roof access for future equipment installation, and details of any existing automation or sensor networks.

During facility tours, observe infrastructure details. Are utility conduits visible and accessible? Are electrical panels adequate for three-phase power? Is the floor flat and unobstructed? Ask current tenants which infrastructure limitations they encountered and whether space constraints complicated operations.

The most expensive automation failures occur when companies select locations without evaluating technical requirements. Suddenly the robot doesn’t fit, power capacity proves insufficient, or layout prevents optimal routing. By the time infrastructure limitations become apparent, relocation becomes the only remedy.

Conclusion

Facility infrastructure determines whether business automation becomes feasible, expensive, or impossible. Successful robotics deployment requires adequate ceiling height, proper floor specifications, three-phase power, and comprehensive data connectivity. Companies implementing automation achieve substantial productivity gains, error reductions, and cost savings. Yet these benefits only materialise in facilities designed to support such systems.

Forward-thinking businesses evaluate facility infrastructure as a core location selection criterion, not an afterthought. Pepijn Amse’s final observation captures this reality: ”Companies often wait to automate, thinking it’s complex. Every day you wait costs money. With today’s technology, even small operations benefit from automation. It’s essential when staff is almost impossible to find. And if it’s not feasible yet, it probably will in a few years.”

Key takeaways

- Ceiling height, floor loading, and three-phase power are non-negotiables for robotics deployment.

- Building overcapacity into infrastructure costs little initially but proves prohibitively expensive to retrofit.

- Future-proof facilities enable automation that delivers substantial productivity gains and competitive advantage.

At Necron Group, we develop logistics properties where tomorrow’s innovations are possible today. Our facilities integrate the infrastructure foundations that enable automation, optimise operations, and future-proof investments.

We understand that successful logistics real estate is just as much about buildings, as it is about enabling the technologies that drive competitive advantage. The sector evolves rapidly and the facilities we develop must evolve alongside it. That’s not just our strategy. It’s our commitment.